Gudgeon Pin (Piston Pin) : Method, Design & Working Conditions

What is Gudgeon Pin?

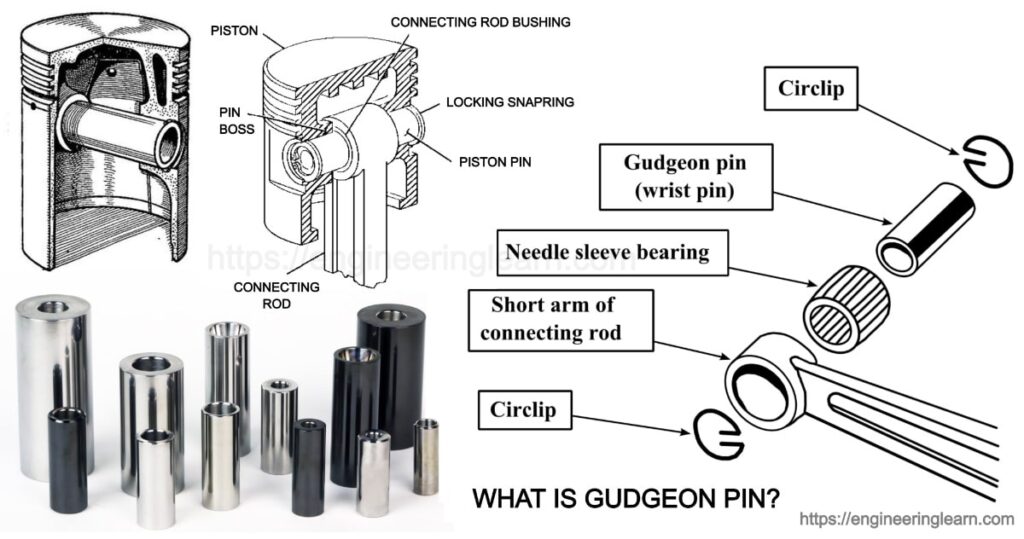

Gudgeon Pin (Piston Pin) : Method, Design & Working Conditions :- The gudgeon pin is mostly found in an internal combustion engine that is found connecting the piston to the connecting rod which acts as a bearing for the connecting rod and pivot as the piston moves. In earlier time the designs of the engine included the ones which were driven by steam and marine engines, wherein the gudgeon pin is located in a sliding crosshead that directly connects to the piston through a rod. The word gudgeon was originated from the word gojoun, from the Middle French word. The first known gudgeon pin started its production in the early 15th century.

The gudgeon pin is known as a forged short hollow rod which is mostly made of a steel alloy having high strength and hardness which might be separated physically from both the connecting rod and piston or crosshead. In the case of small or high-revving automotive engines design of the gudgeon pin is quite challenging. The gudgeon pin operates under the highest temperatures which is experienced inside the engine with most of the difficulties in the lubrication due to its position whereas the small and light remains fit inside the diameter of the piston and does not unduly add to the reciprocating mass.

The basic thing which is required for lightness and compactness needs a rod with a small diameter which is subjected to heavy shear and bending loads, with some of the highest pressure loadings of the bearing in the whole engine. In order to overcome these problems, the material which is used in constructing the gudgeon pin is amongst the most highly engineered mechanical component which are found in the internal combustion engines.

Design Options of Gudgeon Pin

There are commonly two design options available in a gudgeon pin. The design of a gudgeon pin depends on the technological and technical effectiveness.

1. Semi-floating

The semi-floating pin is mostly fixed with respective to the piston through an interference which is fit with the journal in the piston. The connecting rod comprising of a small end bearing acts as the bearing alone whereas in this configuration small end bearing requires a bearing surface only. This is done through processes like electroplating wherein the small end bearing journal with a suitable metal or by inserting a sleeve bearing or needle bearing into the eye of the small end that is provided with an interference fit with an aperture of the small end. It is commonly recommended to replace the bearing sleeve if it gets worn badly.

Other than this configuration there exists a reverse configuration where the gudgeon pin is fixed to the connecting rod rather than the piston which is implemented by using an interference that is installed with the small end eye instead with the gudgeon pin journals in the piston which is functioned as a bearing. It is found that this arrangement is quite difficult to manufacture and to maintain as both the bearing surfaces or the inserted sleeves complicate the design.

Other than this the pin should mandatorily be set precisely so that the small end eye is central. Due to the thermal expansion conditions the arrangement was more popular for single-cylinder engines as compared to multiple cylinder engines comprising of long cylinder blocks and crankcases, until accurate construction became more popular.

2. Fully floating

Fully floating configuration includes a bearing surface which is created within the small end eye, gudgeon pin and the journal in the piston. The gudgeon pins are usually secured with circlips. There is no such interference found which fits in any instance and the pin floats on the entire bearing surfaces.

A gudgeon pin is also commonly known as a wrist pin which is one of the most important component in an internal combustion engine. This is responsible for creating a connection within the connecting rod and the piston. The Gudgeon pins is also accompanied with the connecting rod and the wheels or cranks. The term gudgeon pin was developed in the United Kingdom whereas in the United States and Canada it was termed as wrist pin. There are a number of manufacturers who produce gudgeon pins in order to replacement the worn pins.

The components of the engine comprises of a short tube which is usually made from a forged steel. The gudgeon pin is subjected to a high amount of force during the entire running condition of an engine. It is found that it must successfully endure thousands of piston firings during a very short period of time. The device is quite heavily pressured by an extremely high environment inside the engine which is also subjected to shearing and bending forces from the connecting rod.

Methods of Designing

1. Semi-Floating Pinch-Bolt Small-End-Clamped Gudgeon-Pin

This is a type of method of fastening the rod to the pin wherein the central portion of the pin incorporates a full or partially formed circumferential groove. Once the small-end of the connecting-rod is centrally aligned to this groove, the respective movement takes place within the gudgeon-pin and the piston bosses. This method helps in using a narrow small-end due to which the width of the rubbing surface within the piston and the gudgeon-pin boss is enlarged.

2. Semi-Floating Force-Fit Small-End-Clamped Gudgeon-Pin

This type of arrangement includes the small-end of the connecting-rod wherein its faces are polished with emery cloth and is heated evenly using an oxyacetylene torch at about 503 to 593 K, till there is a colour difference found from pale-straw to dark-blue oxide around the eye. After this the gudgeon-pin is forced through both the piston and the small-end eye is positioned centrally. The small end cools the shrink over the pin and also its relative rubbing movement is kept within the pin and the piston bosses.

3. Semi-Floating Piston-Boss-Clamped Gudgeon-Pin

The gudgeon-pin is clamped to one of the piston bosses wherein the small-end of the connecting-rod is lined up with an interference-fit phosphor-bronze plain bush bearing. This bush helps in locating the gudgeon-pin and thus provide it a low-friction surface. Proper care must be taken in order to not strip the thread in the relatively soft alloy but while tightening the tapered locking bolt. This method is adopted when the bearing properties of the piston material are not correctly suitable for the continuous oscillatory rubbing or are not suitable as heavy-duty.

4. Fully Floating Gudgeon-Pin End-Pads

It is advised that the gudgeon-pins should not be touched by the cylinder directly so that the scoring of the walls can be avoided by their very hard outer edges once they are allowed to float in their piston bosses. There are various methods of preventing scuffing like spherical end-pads made from aluminum, brass, or bronze which aims to act as a buffer within the walls and the pin. While these operations continue, the gudgeon-pin is found revolving freely at both the small-end in the piston that is found having has a tendency to improve the lubrication.

5. Fully Floating Gudgeon-Pin With Circlip Location

This type of gudgeon pin is designed with a fully floating Gudgeon pins which provides the bearing-surface area to the piston-boss bores and also the small-end bronze bush bearing. The engines are found having large pivoting angular movement as well as heavy thrust loads on the piston’s skirt. The double swivel action of the fully floating pin decreases the tendency under the heavy-duty conditions which are used to restrain the gudgeon-pin from sliding side by side. The clips are positively set in the internal circumferential grooves which is formed near the outer end of each gudgeon-pin-boss bore.

How a Gudgeon is Designed?

It is quite challenging to design a gudgeon pin. The device which is used needs to be quite small and lightweight so that it does not add any unnecessary weight to the vehicle and also ensures that it gives a comfortable fitting to the often cramped quarters of the engine compartment. It must also be strong and made from a metal which must withstand a considerable hard use. However, some manufacturers use the rarely known metals in order to produce the gudgeon pins whereas the others rely on the regular stainless steel which are forged in carefully controlled conditions.

Piston Pin

The gudgeon pin is mostly installed in a semi-floating or fully floating configuration which depends upon the design of the engine. It is found acting as a bearing for the connecting rod which allows the rotational movement whenever the engine is in the running condition. Specialized versions are produced for applications like car racing, where engine components need to be especially strong due to the high performance of the engine which creates some unique demands.

When engines are inspected which includes the oil changes, tune ups and various other routine visits to the mechanic, it gives an obvious sign of wear or tear on the components of the engine. In case there is any problem which is found within any of the component like a gudgeon pin, it can be replaced easily. This can also indicate that there is an underlying problem with the engine which needs to be addressed properly. It is important to take the problems of the engine seriously as ignoring this can lead to the catastrophic failures of components or the engine itself. It is noted that the repairs are quite costly but it is also noted that it is cheaper to fix a problem than to wait for something else to break and bear the double expense.

Working Condition of a Gudgeon Pin

The development of the engine was quite quick and its performance improved greatly this is also leading to the great demand for engine parts. The important parts of the engine i.e. piston makes sure about the cyclic gas pressure and the inertial forces at work other than this, the working condition can be responsible for causing the fatigue damage of piston for instance, seat crack of the piston pin. The earlier investigations indicate that the highest stress is found on the top end of the piston pin seat wherein the stress concentration is one of the main reason for fatigue failure. This is the reason which complicates working environment for the piston, on the one hand, the FEA for the piston became more difficult.

Piston Pin

Gudgeon pin has a role in connecting the small end of the connecting rod with the piston by providing a turning pair. This can also turn the relative to the connecting rod or relative to the piston bore or can even turn relative to both. The precondition for this function is that the Gudgeon pin has a sliding fit with both which leads to seizure. Also, the Gudgeon pin should necessarily not be stressed beyond its bearing limit as it is either a hollow or a solid steel cylinder of length roughly five times its outer diameter and which is subjected to only lateral load from the connecting rod.

The piston pin is also used in connecting the piston and the connecting rods inside the internal combustion engine, wherein the piston pin transfers the gas pressure into the connecting rods. The rubbing pair consists of a piston pin and piston pin boss through which the gas pressure gets delivered to the rubbing pair through the piston pin and piston pin boss, and then finally the piston pin might occur bending.

Stresses And Deformation Experienced By Gudgeon Pin

A Gudgeon pin experiences a high amount of deformations and stress specifically in a reciprocating compressor that are used in the Air braking system is predicted scientifically whenever the pin is kept floating fully by surrounding the lubricating oil around it and when starved of oil. Both the analytical approach are found in a finite element method and simple bending theory of beams which is commonly used. Inadequacy of the beam approach is highlighted. The results which are obtained by both of them are precisely compared. Major role of clearance in the piston bore and small end of connecting rod and effectiveness of lubrication are very closely examined. The factor of safety which is associated with the design of Gudgeon pin is also observed deeply.

No comments:

Post a Comment