Types of Hacksaw Blade & Hacksaw Frame

What is Hacksaw?

Types of Hacksaw Blade & Hacksaw Frame :- A hacksaw is a fine-toothed saw, originally designed to cut metal whereas a bow saw is the equivalent saw for cutting wood. Hacksaws are hand tools used to cut metal that is too thick or hard for the cutters.

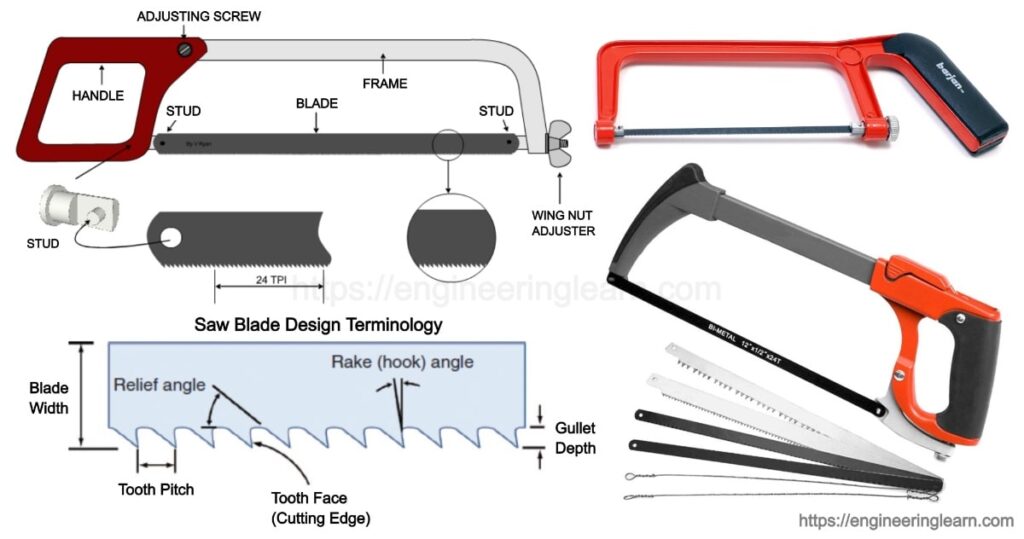

A Hacksaw consists of basically two main elements:

1) A frame with a handle

2) A blade.

Hacksaw blades are usually classified as either flexible or hardened; the variations in terms of coarseness, teeth pitch and length also have to be taken into consideration when you are choosing the proper hacksaw for your task.

Hacksaw Design

Most of the hacksaws are a type of handsaws with a C-shaped walking frame to hold the blade under tension. Such type of hacksaws usually has a handle, mostly a pistol grip, having pins for joining a narrow disposable blade. To accommodate blades of different sizes the frames may also be adjustable. A screw or some other mechanism can be used to put the thin blade under tension.

In most of the frame saws the hacksaws, the blade could be installed on the teeth having its face towards or away from the holder which is used in cutting operation whether on the push or the pull stroke. Normally for cutting vertically downwards the hacksaw blades are set to be facing forwards with work held in a bench vice.

Parts of Hacksaw

Following are given the main part of a hacksaw:-

1) Hacksaw frame

2) Hacksaw blade

3) Adjustable wing nut

4) Adjustable screw

5) handle

6) stud

1. Hacksaw Frame

Its shape is like the English letter “C” of the English language. On one of the ends of these arms, there is a handle is fixed and on the other end, there is a pin is fixed. A hacksaw blade is first fitted on these pins and then it is tightened according to need with the help of a flying nut or the wing nut. Mainly there are two types of hacksaw frames which are as follows:

Types of Hacksaw Frame

Following are given the two main types of hacksaw frames: the first one is the Fixed Hacksaw Frame and the other one is the adjustable Hacksaw frame

1) Fixed Hacksaw Frame

To make this type of hacksaw frame, a portion of the flat iron strip is bent at the right angle. In this kind of frame, the hacksaw blades having a specific size can be fixed neither of the short size or long size. There are two types of handles that are used here:

1- Straight handle

2- Pistol type handle

2) Adjustable Hacksaw Frame

In an adjustable type of hacksaw frames, the structure is a little different from a fixed frame. The frame of the adjustable hacksaw is made in two parts. These components can be adjusted at various lengths. Due to this in this hacksaw, big and small hacksaw blades of the different types can be used.

There are sufficient numbers of pin and channels to pull, adjust and set them. These types of handles are used in this hacksaw:

1- Straight handle

2- pistol-type handle

3- Tubular type handle

4- Flexible Blades

2. Hacksaw Blade

The standard hacksaw blade lengths are 10 to 12 inches (250 to 300 mm). Blades can vary in size and be as small as 6 inches (150 mm). Powered hacksaws generally use large blades in a variety of sizes, or small machines use the same hand blades for small operations.

The pitch of the teeth can be from 14 to 32 TPI (teeth per inch) for a hand blade, with nearly 3 TPI for a large power hacksaw blade. The thickness of the material which is to be cut decides which blade is to be used, with a minimum of three teeth in the material. As hacksaw teeth are so small in size, they are placed in a “wave” set. As for the other saws they are placed from side to side to provide clearance or kerf when sawing, but the set of a hacksaw changes generally from tooth to tooth in a curve, rather than alternate teeth set left and right.

‘Low Alloy’ Blades

Types of Hacksaw Blade: – Hacksaw blades are normally very brittle, so care needs to be taken by the operator to avoid brittle fracture of the blade. Early blades which were made of carbon steel are now termed as ‘low alloy’ blades and are relatively flexible and soft. They prevent breakages, but also wore out rapidly. Except where cost is a major concern, this type is now rarely used and considered as out of date. ‘Low alloy’ blades are the only type available for the junior hacksaw, which results in the limited usefulness of this otherwise popular saw.

For several decades now, high-speed steel has been used for the teeth of hacksaw blades, providing greatly improved cutting and tooth life. In beginning, these blades were first accessible in the ‘All-hard’ mode which cut perfectly but it was very weak. This resulted in their limited practical use to bench work on a work piece that was firmly held in a vice. A softer form of the high-speed steel blade was also available, which wore better and resisted breakage to an extent, but was less stiff and so less preferred for accurate sawing.

Types of Hacksaw Blades

The Following given are the main types of hacksaw blade:

● Course Grade Hacksaw Blade

● Medium Grade Hacksaw Blade

● Fine Grade Hacksaw Blade

● Superfine Grade Hacksaw Blade

● all Hard Blade

1. Course Grade Hacksaw Blade

This type of Hacksaw blade is practiced for cutting width of mild steel, copper, aluminum and brass etc. these are having 14 to 18 teeth per inch.

2. Medium Grade Hacksaw Blade

This type of Hacksaw blade is practiced for cutting all kinds of metals like cast iron, tool steel, aluminum, brass, high carbon steel etc. From 20 to 24 TPI (teeth per inch) are cut in this hacksaw blade.

3. Fine Grade Hacksaw Blade

This type of hacksaw blade is mainly used to cut the thinner pipes, sheets, tubes etc. These blades are having 24 to 30 dents per inch.

4. Superfine Grade Hacksaw Blade

For cutting exceptional hard metals and light metal sheets, a very thin kind of hacksaw blade is utilized. These blades are having 30 to 32 dents per inch

In all the hacksaw blades of different categories stated here, the teeth are made on one or both sides. These blades are strengthened in two separate manners and this depends on their characteristics.

5. All Hard Blade

The nature of these blades includes that they are hard and tempered only except the ends where they have holes which make them slightly weak. These are utilized for cutting cast iron or mould iron etc.

6. Flexible Blade

In blades of this nature, only the cutting teeth and nearby part is hardened and tempered. But this method becomes flexible and it has a low risk of being brittle and get broken in the event of a shock. These blades are utilized for cutting thin sheets, pipes, curves etc.

Methods of Using Hacksaw

- Hacksaw blade should be installed on the frame very accurately. It should not be very firm nor very loose.

- The job which is to be cut should not be held in a vice much high otherwise there would be vibrations in it.

- Hacksaw blade should not be allowed to become slanting while using a hacksaw. There are possibilities that it may break because of slating

- If the blade starts cutting in a slanting manner we should start a fresh cut.

- The new blade can break if it is operated in an old slot.

No comments:

Post a Comment