Types of Cutting Tools Machine

Types of Cutting Tools Machine :- Cutting tools are used to remove metal from work piece. Generally tool must be harder than the work material.

The selection of the tools depends upon various factors are following:

- Design of the tool

- Production volume

- Rigidity & condition of the machine

- Chemical & physical properties of work piece material.

Properties of Cutting Tool Material

- Hot hardness: tool is capable of withstand to high temp during operation without losing any cutting efficiency (Property).

- Wear resistance: it is basically the friction between the tool & work piece while contacting during operation. If tool doesn’t possess the adequate wear resistance property then it will fail quickly (without meeting surface finish requirements).

- Low friction: The coefficients of friction between work piece & tool have to be lower. Less friction reduces the heating & wearing in the tool material.

Cutting Tools Materials

following tool material having suitable heat treated requirement manufacturing of machine tools.

- C.S steel

- High speed steel

- Cemented carbide

- Diamonds

- Ceramics

Different Types of Cutting Tools Machine

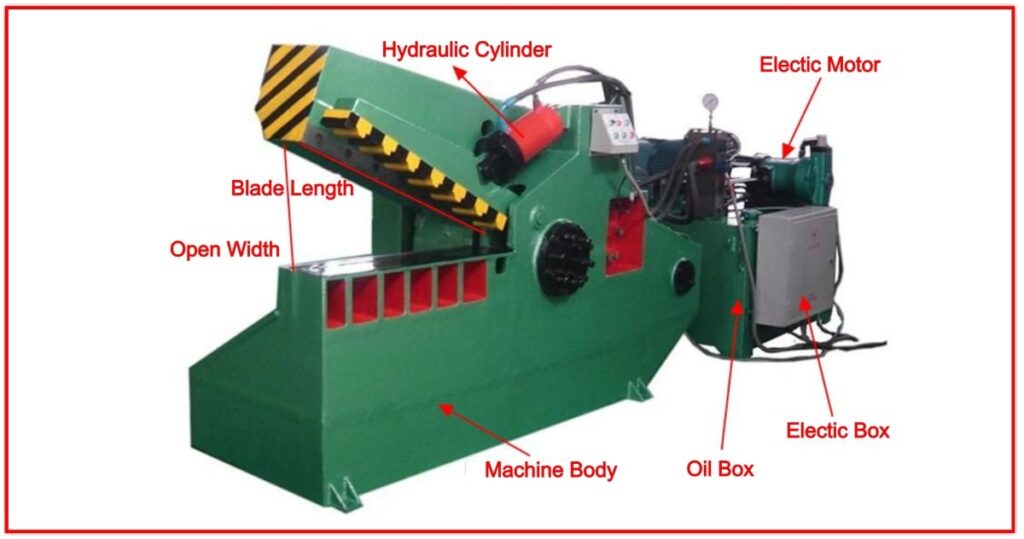

1. Alligator shear

It is equipped with lever shear with hinged jaw. Power provided through flywheel or hydraulic cylinder. They are used for cutting long metal stocks or scrap, used where accuracy is not needed to pin point.

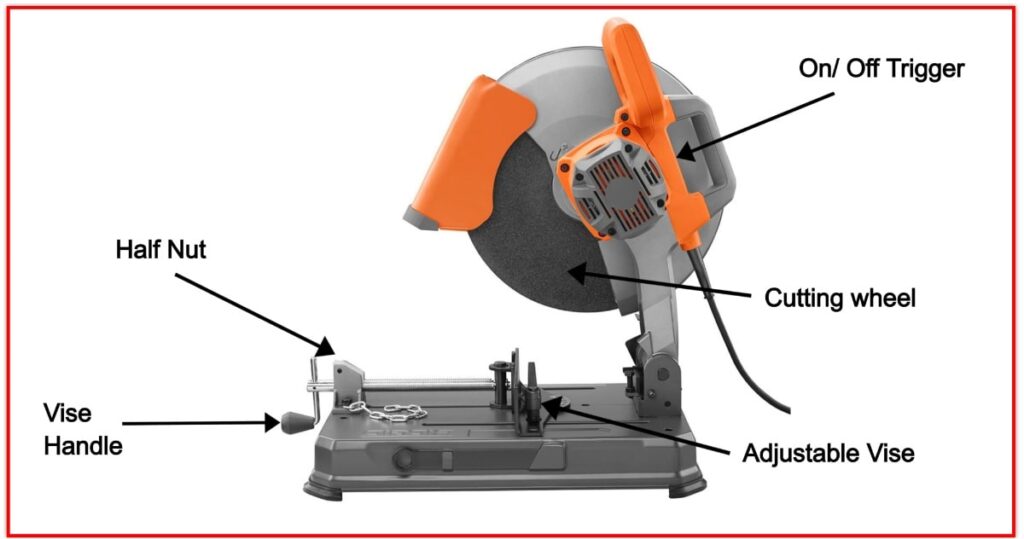

2. Abrasive saw

Abrasive saw also known as cut-off saw. Abrasive saw certainly used for hard material (metal). Abrasive saw comes with portability mode that made jobs quite easier.

3. Bandsaw

They are used in cutting metal & even hard timbers. Bandsaw provides the uniform cutting as it is well equipped with evenly distributed teeth load. Band saw consists of continuous band of metal with teeth to one edge for cutting out the job (this tool uses blades for cutting).

4. Diamond saw

They are used in cutting stone, cobalt, asphalt bricks, glass in construction work. It also uses to cut the semiconductors materials in an I.T Industry. It comes with different variety in diamond saw blades like circular blades, drill & surface grinding wheels.

5. Tungsten carbide steel

TCT blades are often used in industry to cut metals, aluminum, wood or plastic. TCT edges consist of separate piece of material bronzed, welded or clamped to separate body.

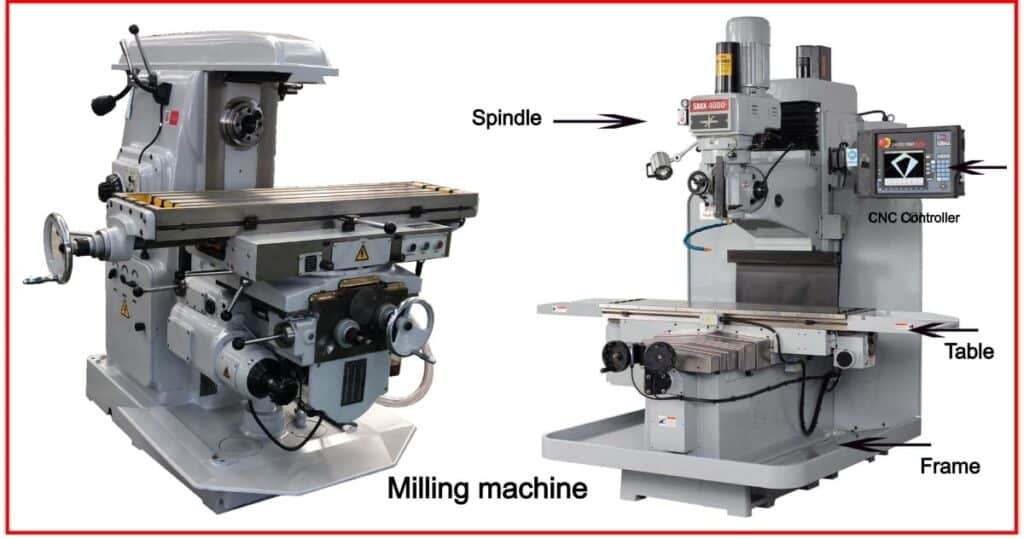

6. Milling machines

Milling machines are also known as MTM’s (multitasking machines) which possess the capability of milling & turning the materials as well. It mainly consists of cutter installed at the top which used to remove unnecessary past from the work piece. It comes with 2 variations in orientation: horizontal/ vertical. Milling process composed of major 3 steps to complete an operation: Milling cutting, surface and gang milling.

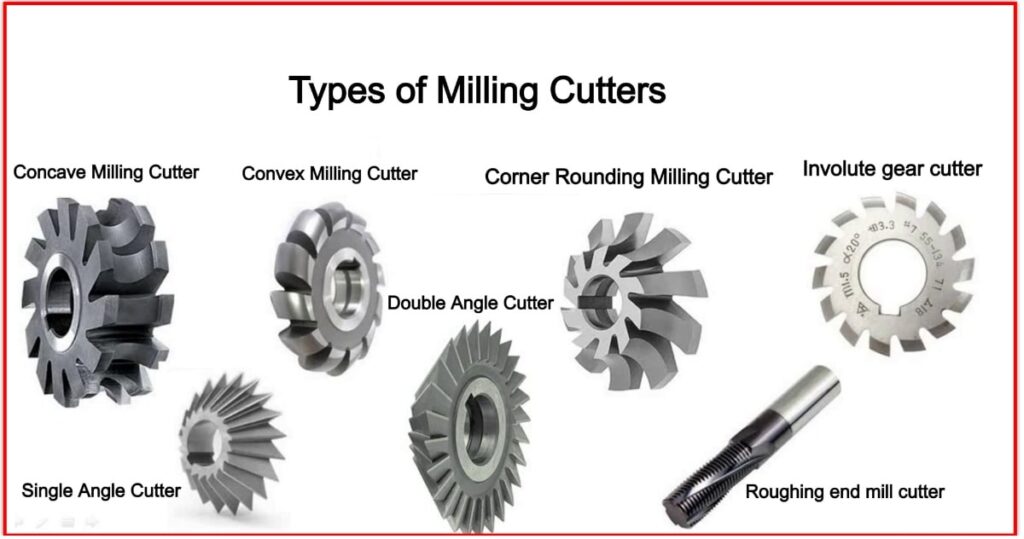

7. Milling cutters

They are tools used on the milling machines. They remove the material by their movement within the machine.

8. Drill press machine

It is used for producing holes in hard substances. The drill is in contact with rotating spindle and fed to the material Work piece.

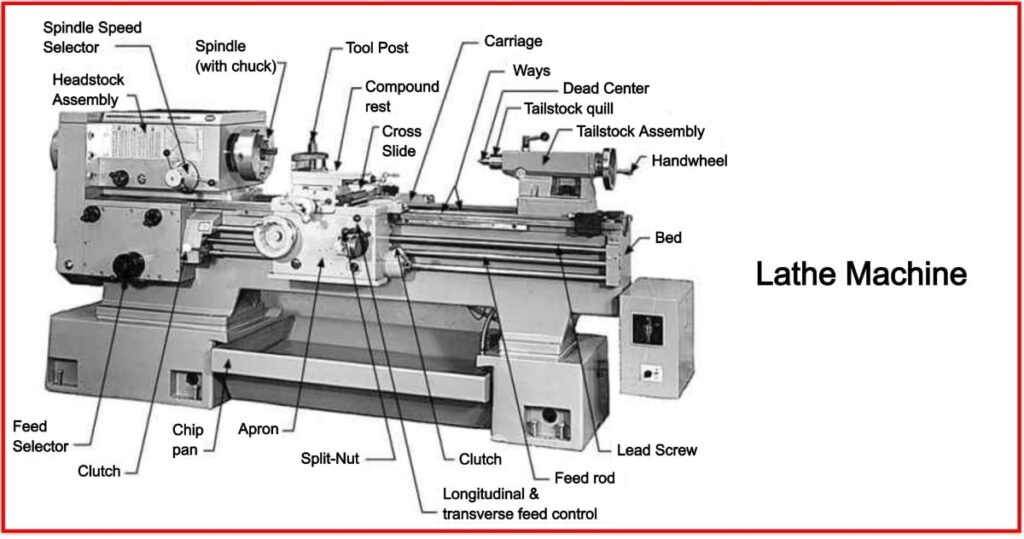

9. Lathe machine

It is the machine that helps in shaping several material pieces into the desired shape. Lathe machine uses it axis (when work piece material is on faceplate) to perform various operations like cutting, facing or deformation etc. The most commonly used lathes are wood working lathes. Lathe machine mainly consist of two ends named headstock & tailstock (material piece to be placed between). Clamping is also fixed on to the machine for the rotation of axis (with the help of faceplate).

According to shape of the cutting tool:

- Solid: solid types tool are used in turning operation like lathe turning tool.

- Tool bit: tool bit are non rotary cutting tool, usually used where shaping, planning etc. needed

- These are single point cutting tools that having one cutting edge. Example: lathe turning tool fixed in the holder, cobalt etc.

- Tipped tool: It is made up of different types of materials. Cutting portion and machine body composed from the different materials.

- Pointed tool: In this tools tip is so fine and edges are present in single line & ends in the same line too.

According to type of cutting:

- Orthogonal cutting: in this type of cutting the cutting edge is perpendicular to the direction of motion the tool. E.g. 2D cutting for square shoulders operations.

- Oblique cutting: in this cutting the angle between cutting edge & direction of the tool motion is anywhere except 90 degree. E.g. 3D tool mostly used in turning operation.

No comments:

Post a Comment